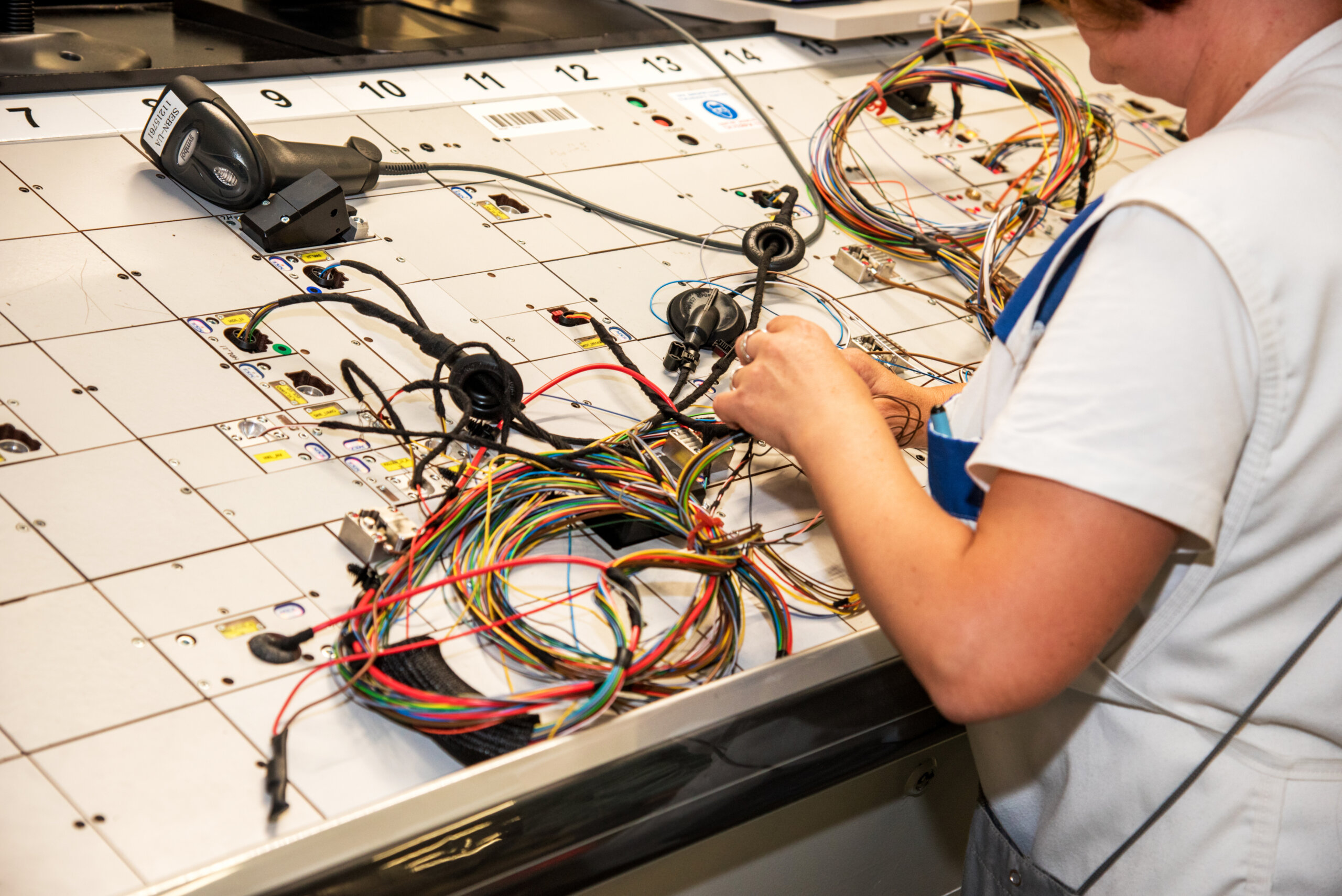

Prototype Wire Harness Assemblies

Minimize labor needs and meet your production timelines with custom electrical wire harness prototype development and manufacturing.

Cost-Effective Designs & Development

Whether you need a new design or the physical development of your prototype, we can help. Our expert teams fabricate custom electrical harness prototypes with the most cost-effective solutions for tooling, component selection, and labor.

Regardless of its complexity, we’ll ensure your prototype meets production quality standards so you can effectively validate your production design.

Rapid Turnaround to Meet Your Production Timelines

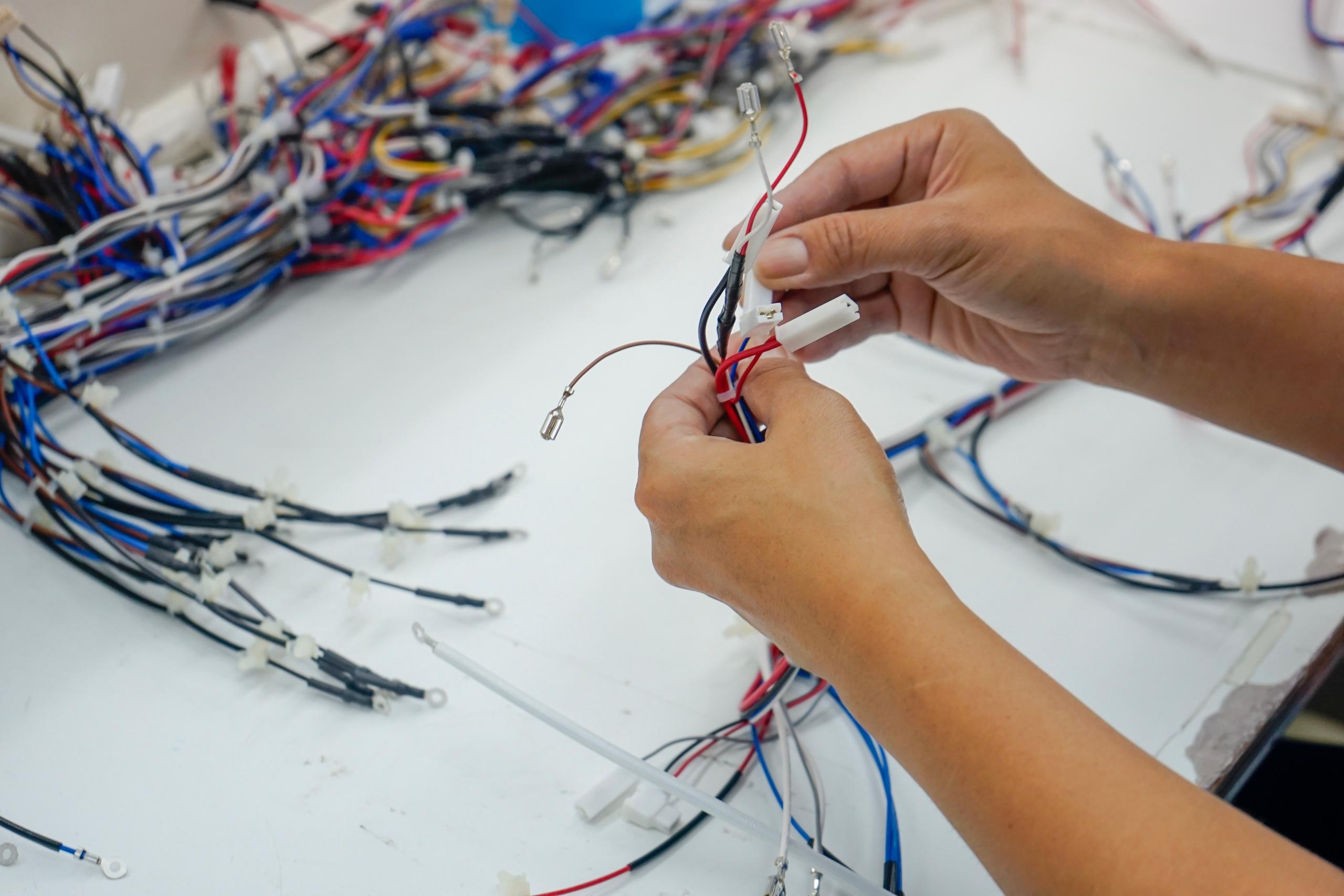

At RFA, we understand the urgency of swiftly receiving your prototype without compromising quality. To achieve this, we integrate advanced techniques like ultrasonic splice welding into our custom prototype manufacturing process. Compared with more traditional welding methods like crimping or resistance welding, ultrasonic welding offers several advantages, enhancing the overall quality of our prototypes. These benefits include producing higher-quality weld joints, improving process control, and significantly reducing energy consumption.

By utilizing this innovative approach and other technology coupled with our process, we can often guarantee the delivery of your prototype within a few weeks without sacrificing the high standards you expect. Our prototype services include:

- Sourcing and Selection of Best-Performing Components

- Schematics

- Low-Volume Prototype Development

- Testing and Quality Control

Wire Harness Design and Quality Control

Each wire harness begins with a detailed schematic that acts as a blueprint, outlining all essential components and their connections. Taking wire routing into account is essential to a wire harness’s success. We look to reduce complexity that minimizes potential errors during wire harness prototype assembly. Our approach to wire harness design ensures that we can deliver high-quality, tailor-made prototypes that meet your specific requirements. By focusing on precision in our schematics, strategic routing, and careful component selection, RFA guarantees prototypes that are not only efficient but also align perfectly with your production goals and deadlines.

Following the fabrication of the wire harness prototypes, each assembly undergoes testing and quality control to ensure it meets the highest standards. This includes continuity checks and functional testing to validate the electrical integrity and performance of the wire harness. This dual focus on technical precision and endurance testing ensures that each wire assembly prototype not only functions as intended but also stands up to real-world conditions, aligning seamlessly with your production quality expectations and timelines.

A Trusted & Flexible Custom Wire Harness Manufacturer

The success of your prototype is our top priority. We design and build each harness to fit your unique requirements through a collaborative, tailored approach. With over 50 years of engineering experience, our teams have a unique blend of expertise, creativity, and problem-solving abilities, making us a trusted outsourcing partner.

Want to Learn More and Discuss Your Project?

We’re here to support you. Contact us today to get started.