Our industry demands that modern machines offer features for reliability, productivity, safety, ease of use, intelligence, remote connectivity and automation of tasks to maximize ROI. To deliver, we must develop specialized electronic and embedded control systems for these machines.

What Is Electronic Control Systems Integration?

Electronic control systems integration is only one part of the overall systems integration process. In fact, the process includes numerous systems that must interact heavily with each other.

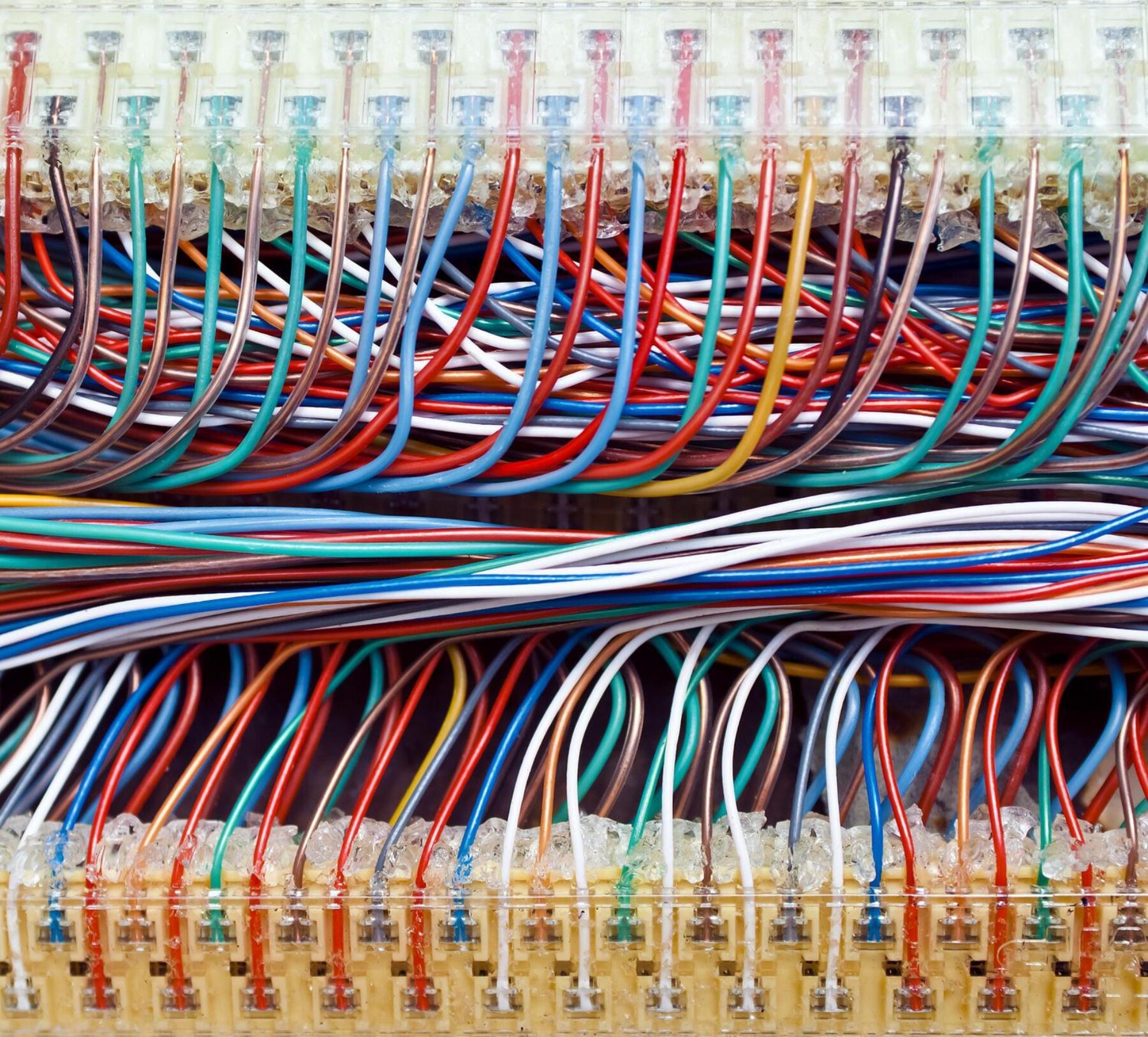

These systems often include electrical, hydraulics, powertrain and the operator’s interface, just to name a few. The visible end product includes control buttons, joysticks or a touchscreen which interact with behind-the-scenes embedded computers running custom programs to change anything from lights to engine speed, things only limited by your creativity.

The seamless experience users are accustomed to doesn’t just happen from dropping in a casually-created program or a few lines of code. Instead, an “engineered” system must be implemented to cover requirements for rarely encountered conditions. Plus, they must cover requirements for diagnostic feedback that could be required to troubleshoot and isolate problems from any other system.

As a result of detailed engineering, we can prevent unintended outcomes, minimize the number of bugs in the system and support the extended needs of machine service.

Electronic Control Systems Integration Requires the Ability to Scale

Just like any other system, an electronic control system must be:

- Maintainable

- Testable

- Reliable

It must have diagnostics and version control. And as systems become more complex, development requires a larger effort, especially to resolve safety concerns.

Some simple development projects may require a single person using an off-the-shelf solution. Yet, complex projects can scale to teams of embedded software engineers. These teams may develop custom electronics, custom toolchains and highly structured testing environments to achieve results that meet functional safety requirements.

In product development, the electronic control system must be architected during the early stages of the process. This will ensure the viability of the product in terms of system functionality, technical limitations and safety implications.

An RFA Systems Integration Sample Project

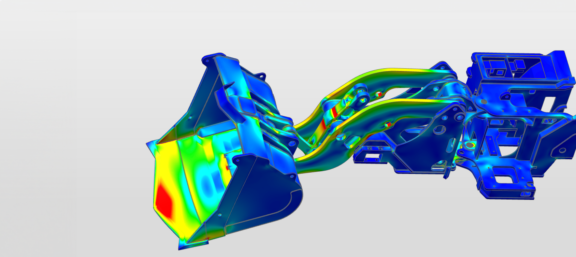

RFA Engineering recently completed a multi-system project with integrated mechanical, electrical, hydraulic and electronic controls. The client came to us with a proof of concept design that described basic functionality and provided a requirements baseline. Our role was to refine the requirements and redesign the machine to be production-ready.

After discussing requirements, including the selection of sensors and I/O, we helped them select the Danfoss Plus+1® product platform. The platform includes a controller, GUIDE® development environment and a touchscreen display as the backbone of the system. With the help of a Certified Functional Safety Expert, we conducted a functional safety review to uncover any obstacles that may hinder introducing the product into the EU.

Challenge: Simplifying Through Sequencing

The primary challenge of the project was to execute several semi-automated operation sequences to simplify the coupling and de-coupling of machine attachments. This occurs while the operator navigates the machine from a remote camera that displays on a touchscreen.

As a new product to the market, the client understood the expectations of the end-user better than our team. An initial proof of concept effort was required to iterate the usability of the system with the client.

After operation sequence definition, we proceeded to the production-intent program development, which includes refinement of the logical operation sequences. This includes corner conditions and the development of diagnostic capabilities to provide system fault detection and troubleshooting aids. We also carefully designed the touchscreen UI menus to align with our client’s needs.

Testing of the Electronic Control System

Testing was conducted at several levels. During initial development, a typical hardware bench set-up was used for testing, progressing to full testing of all systems on the physical machine. As we continued to add features and as requirements changed, we used LabVIEW products to run automated hardware-in-the-loop testing to isolate issues before installing field updates.

We added additional features to the control system to facilitate data collection and establish mechanical load cases that occur during machine operation.

Our team continues to support this client with periodic changes. We created and continue to maintain the full development environment and version control system for this effort. At the same time, we allow the client to take control at any time and they maintain full ownership of the related IP.

Vendor-Neutral Systems Integration Services by RFA Engineering

Our team at RFA Engineering knows how to use the Danfoss PLUS+1® and GUIDE® tools, but our capabilities don’t stop there. We have a wealth of experience in a wide range of tools. We’re completely vendor-neutral, which allows us to do what it takes to complete your project.

We can help you select the right technology to build your very first electronically controlled system. Or, we can work with any development infrastructures and processes you may already have in place.

To learn more about our systems integration services or to discuss your new project, give us a call at 952-843-2700 or send us a message.

Continue Reading

Augment Your Engineering Team Through Flexible Outsourced Staffing

As engineering needs grow more complex, businesses face constant challenges in meeting specialized demands. Rather than hiring for every skill set, companies are expanding their expertise through outsourcing.

Read MoreAccelerating Innovation with Finite Element Analysis

Simulation has transformed how engineers approach design and development. Finite Element Analysis (FEA), a cornerstone of modern simulation tools, allows teams to create virtual environments for testing and…

Read MoreTransforming Fleet Management with IoT and Data Lakes

Fleet management has transformed from basic tracking into a sophisticated system of real-time analytics and intelligent operations management. This evolution is largely driven by IoT technology integration,…

Read More

Want to Learn More and Discuss Your Project?

We’re here to support you. Contact us today to get started.