Simulation has transformed how engineers approach design and development. Finite Element Analysis (FEA), a cornerstone of modern simulation tools, allows teams to create virtual environments for testing and refining designs. This approach goes beyond traditional methods, enabling engineers to explore innovative solutions, tackle complex challenges, and deliver optimized products. By integrating FEA into their workflows, companies enhance their ability to innovate and maintain a competitive edge in dynamic markets.

Reducing Time to Market with Simulation

In fast-paced industries, every day counts. A delay in product launch can mean missing critical opportunities. Simulation, especially with FEA, accelerates development by enabling engineers to test and refine designs digitally. This virtual-first approach allows potential issues—such as structural weaknesses or stress points—to be identified and resolved early. With faster adjustments and fewer setbacks, products reach the market more quickly and confidently.

Optimizing Performance for Real-World Use

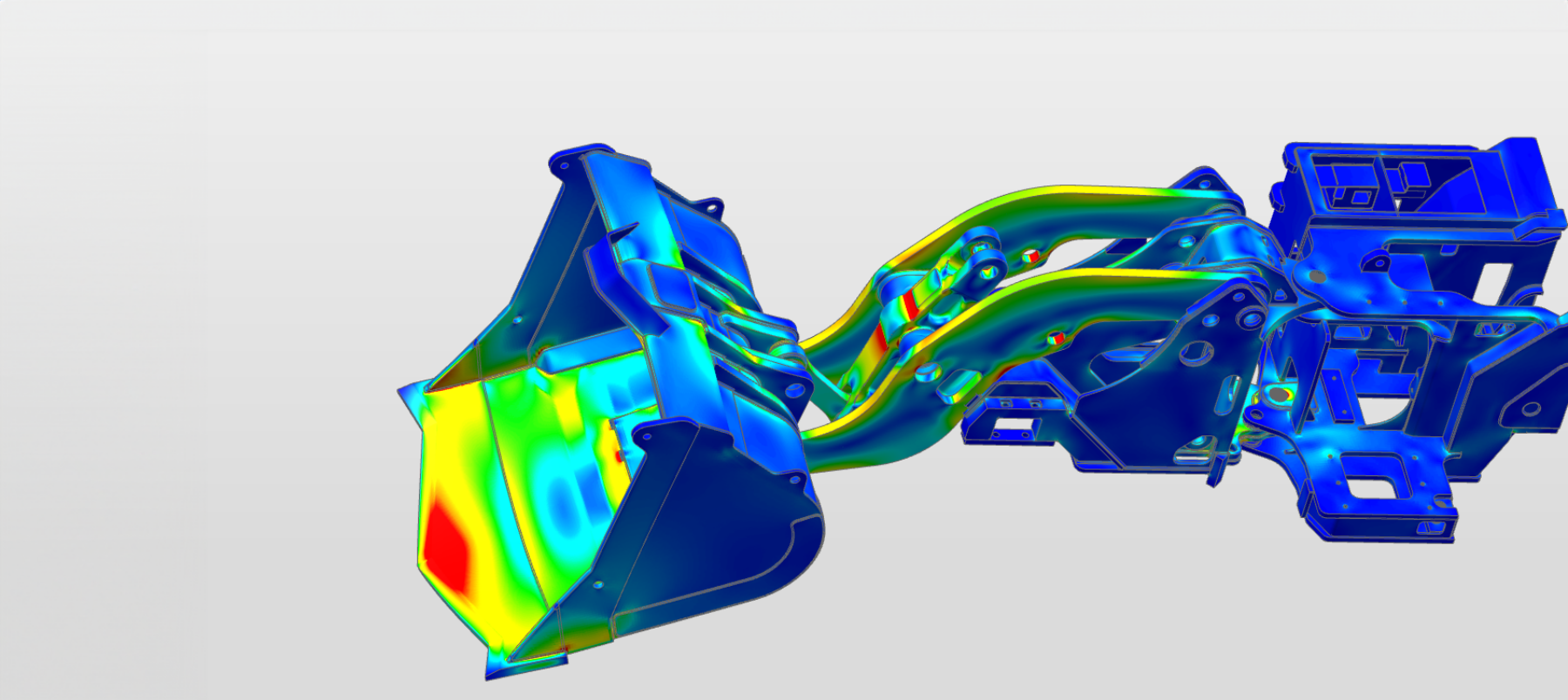

Reliability and performance are paramount, especially in fields like automotive, mobile electronics, and electronics, where products face rigorous conditions. Engineers optimize performance by analyzing a product’s behavior in virtual environments, such as evaluating aerodynamic efficiency, thermal regulation, or response to structural and fatigue loads. Tools like Finite Element Analysis enable structural analysis of mechanical systems, helping enhance reliability and ensure products meet performance standards. These capabilities extend across a variety of simulation methods tailored to specific needs, including:

- Static, Linear Analysis: Evaluates stresses under constant loads to ensure structural integrity.

- Modal Analysis: Examines vibration modes to optimize designs for dynamic environments.

- CFD (Computational Fluid Dynamics): Analyzes the flow of gases and liquids and heat transfer to optimize efficiency and performance.

- Nonlinear Analysis: Accounts for complex material behavior, such as deformation or buckling.

- Dynamic Analysis: Studies time-dependent forces to assess performance in real-world conditions.

- Fatigue Analysis: Predicts material failure over repeated cycles to improve durability.

- Multiphysics Analysis: Examines how different properties, like thermal and mechanical forces, interact as they change together over time.

Rapid Iteration through Simulation

Innovation is an iterative process, and FEA-powered simulation makes this cycle faster and more cost-effective. Traditionally, each design required a prototype for testing—a process that could take weeks or months. Simulation allows engineers to test multiple variations quickly in a virtual space. This flexibility supports creative problem-solving, letting teams respond rapidly to design challenges and evolving requirements.

Predicting Failures and Reducing Warranty Claims

Failures in the field are costly—not only in repairs but also in lost customer trust. Simulation offers a proactive way to reduce these risks by predicting potential failure points long before a product is released. Engineers can simulate how products will perform under extreme conditions or over time, identifying stress or fatigue points. For instance, FEA can help predict how a complex assembly will hold up under continuous heavy loads or fatigue duty cycles. This approach reduces the risk of unexpected failures, lowering warranty claims and increasing customer satisfaction.

Driving Innovation with Simulation

Today, engineering simulation isn’t just for specialists—it’s an essential part of competitive product development. By reducing time to market, optimizing performance, enabling rapid iteration, and predicting failures, simulation empowers companies to push the boundaries of innovation. At RFA Engineering, we deliver advanced simulation and testing services tailored to each project’s unique needs. From early design validation to in-depth analysis, our team uses FEA and other simulation techniques to provide insights that drive better outcomes across industries.

For more on how simulation can support your next project, reach out to RFA Engineering today.